Uplift Bridge Bearings

Add uplift restraint to a bridge design with modified Disktron Bearings

Uplift Restraint for Seismic Zones

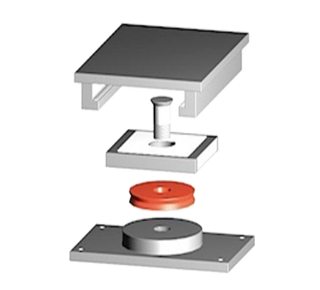

RJ Watson’s Disktron Bearings can easily be modified to provide uplift restraint for seismic applications. Uplift forces are also seen on some curved girder bridges and in flood-prone regions, where high water can result in the bridge becoming buoyant. For uplift restraint, the Disktron Bearing’s high strength machined shear pin is modified so that the upper and lower bearing plates can’t separate.

Uplift

Uplift, Movement & Rotation. Simultaneously.

The pin acts much like a trailer hitch connecting a trailer to its vehicle. The expansion bearing’s upper slide plate is also modified so that it lips under the upper bearing in order to resist uplift force. Fully assembled, the modified Disktron Bearing can accommodate uplift load, movement and rotation simultaneously—a feature unique to this type of bearing.

Shear Resisting Mechanism

A large diameter high strength steel pin transfers horizontal and uplift loads from the upper bearing plate to the baseplate and isolates shear and tension loads from the Polytron Disc.

Design and Test Your Bearings

The experienced engineers at RJ Watson can help you find the right bearings for your project with our no cost, no obligation design services, as well as our extensive testing capabilities.

FEATURED PROJECTS

Dulles Metro Line

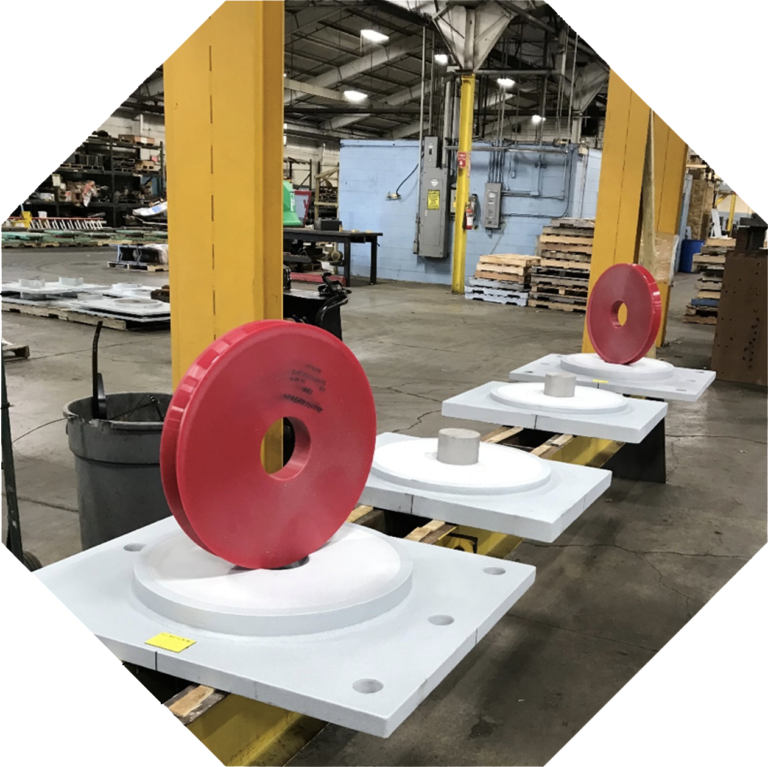

Three of the steel plate girder bridges on the Dulles Metro Line Project featured Disktron Bearings which ranged from 225 kips to 900 kips in vertical load capacity.

The rotational capacity of these bearings was 0.025 radians and the displacements on the expansion bearings ranged from 3 to 6 inches. One of the bridges also required uplift restraint, which was easily accommodated with the Disktron design.

I-74 over Mississippi River

R. J. Watson engineers had to take special consideration in the design of the disc bearings to accommodate a service uplift load of 102 kips, or 13% of the vertical load.

Four of the bearings were designed to absorb lateral arch structure loads, while at the same time allowing rotation, and vertical, and longitudinal displacement. The solution was to use disc bearings oriented vertically, and they were called “Wind Tongue Bearings.”

When the experts have questions, they turn to

RJ Watson

RJ Watson works with engineers, contractors and owners to create bridges and highways that reliably serve their communities while simultaneously solving engineering challenges. RJ Watson is available to work with you to create a cost effective solution for your specific project.